| 洛杉矶 |

| 圣地亚哥 |

| 橙子 |

| 河边 |

| 帝国 |

| 文图拉 |

| 圣贝纳迪诺 |

For this week’s meal spotlight, we will show the process of our Fenugreek Green Curry Chicken Thigh. This delicious dish incorporates a Mediterranean herb called fenugreek, which provides a maple syrup-like flavor to the dish. The fenugreek flavor compliments the green curry and cilantro turmeric sauce very nicely.

For this meal preparation begins on Tuesday. The first step we will dive into is preparing the fenugreek green curry base. Second, we will make the cilantro turmeric sauce. Next, we will prepare the produce that is used in the meal. Finally, we will season and cook the chicken thigh.

The fenugreek green curry base is what is going to provide this dish with its bold flavor. Our experienced culinary team and management team have gone through a deep research and development process to develop this base. The base will include Spanish onions, garlic, ginger, coconut milk, green curry paste, basil, cilantro, lemon juice, lime juice, white sugar, chicken stock, jalapeños, and green peppers. All of these ingredients are cooked on our state-of-the-art tilt skillet. The tilt skillet allows us to cook large batches of food while maintaining the consistency of all the ingredients inside. The tilt skillet is a huge component of our kitchen due to its efficiency (learn more about the advantages of a tilt skillet here).

Our cilantro turmeric sauce is a yogurt-based sauce that is made in-house and perfectly complements the fenugreek green curry. The yogurt is mixed with sour cream, jalapeño, lime juice, lemon juice, turmeric, cumin, coriander, onion powder, and olive oil. Our world-class hand mixers ensure all the ingredients are blended to a perfect consistency. These ingredients create a tangy flavor that pairs very nicely with the bold curry flavor.

The vegetables we will be using for this dish are bok choy, red peppers, carrots, peas, snow peas, and eggplant. Today, we will only be preparing the red peppers, bok choy, and eggplant.

The culinary team starts by chopping up the bok choy to get it ready for being cooked on Wednesday.

Next, using our pepper slicer we slice all of the red peppers. It is important that all of the peppers are sliced to identical sizes. This ensures they will cook evenly, giving all clients the same experience.

Finally, we cook the eggplant in our rational oven. Our rational oven is a convection oven that only uses as much power as needed. This is a huge advantage for us. For our customers, rational ovens are extremely accurate and make sure that even large batches are all cooked to a consistent temperature. The eggplant is added to sheet pans with just the right amount of oil to prevent sticking. Throughout the cooking process, we test the eggplant for consistency until it is at an acceptable level.

We will cook the chicken thighs for our final step of the day. We begin by seasoning the chicken thighs with salt and pepper. The chicken thigh does not need a heavy seasoning blend because it will be added to the curry later in the week. Typically, when we cook our chicken breasts we sear them one day and finish the cooking later in the week.

For this specific chicken thigh dish, we take a different approach. The chicken thighs are placed on our baking sheets without parchment paper. The sheets are placed onto the speed racks and moved into our rational ovens. While in the oven the sheet pans get so hot we can sear the chicken and cook it simultaneously. After the chicken reaches an internal temperature of 165 degrees, we test the flavor. Our culinary team re-seasons as necessary before being moved to the fridge until it is ready for Wednesday.

On Wednesday, we will finish off our fenugreek green curry and cook our jasmine rice. We will also go more in-depth on some of the equipment we use that allows us to produce such a high-quality product.

To start the day we will begin the completion of our fenugreek green curry. The piece of equipment we use to finish off the curry is the tilt skillet we touched on earlier. The tilt skillet is so useful because of its ability to cook large batches of food at once. In addition to this, it has excellent temperature control. We can avoid overcooking or overheating and cook the food in a much smaller amount of time.

First, we cook the carrots, bok choy, and red peppers over medium heat. By adding these ingredients first they can cook for longer and have better consistency with the meal.

Next, we add the chicken and eggplant. Since these have already been cooked they do not need as much time as the raw vegetables above. Shortly after this, we add the peas and snow peas. After everything in the tilt skillet has reached the desired consistency, we then drain the water out.

The final step of the process is adding the fenugreek green curry base. Once all the elements have had time to absorb the curry’s flavor we start our taste-testing process and add seasoning where needed.

The jasmine rice preparation will exhibit the use of our blast chiller. The blast chiller is able to take the temperature of our freshly cooked product from 165 degrees to 38 degrees in less than 30 minutes. This retains the important nutrients and vitamins and also stops the growth of bacteria.

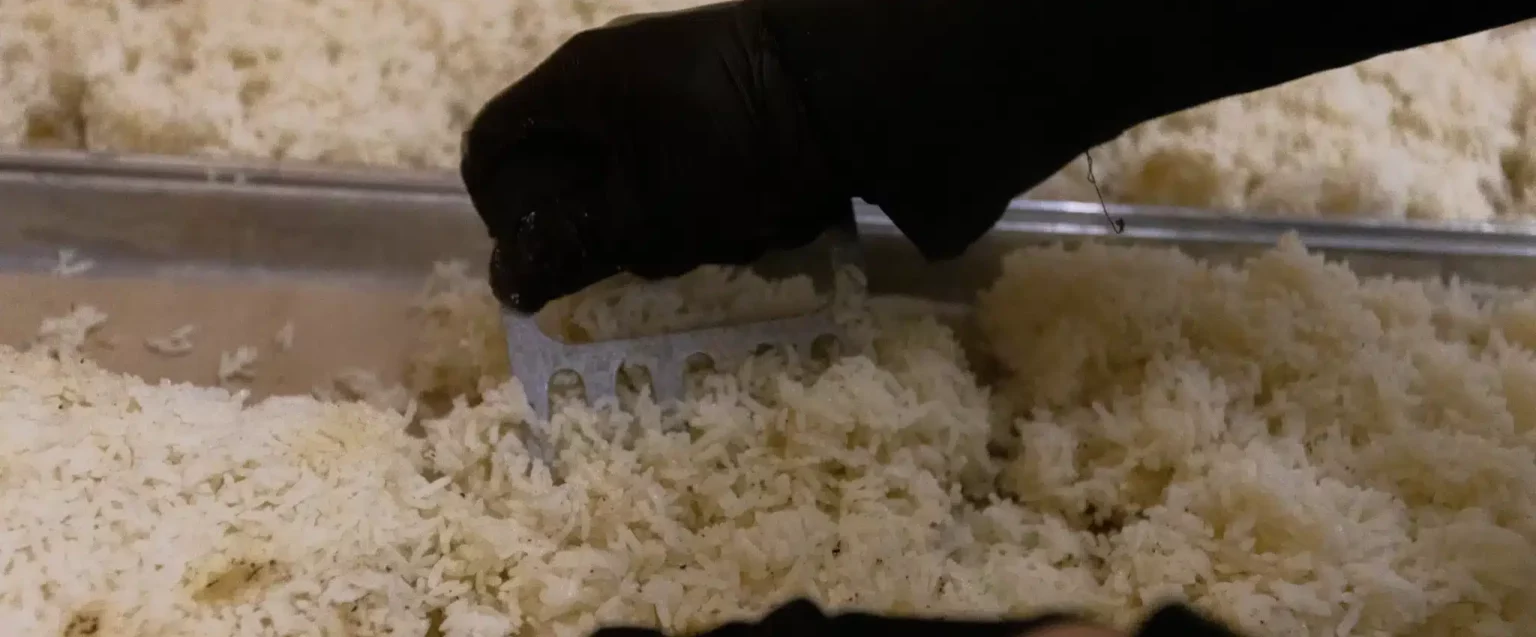

The jasmine rice is first mixed with salt, pepper, salad oil, onions, and chicken stock. Once mixed, it is then placed into our rational convection oven. Once the rice has reached a temperature of 165 degrees it is removed from the oven and immediately flipped into sheet pans and separated. Separating the rice prevents overcooking. The sheet pans are then loaded onto speed racks and moved into the blast chiller to lock in the moisture. After the blast chiller, they are moved into fridges until it is ready to be plated.

For our final day of preparation, we will be plating and packaging our Fenugreek Green Curry Chicken. To begin the plating process we first put in our sauce cup full of cilantro turmeric sauce. Next, we put in the jasmine rice and lastly the fenugreek green curry chicken thigh. The chicken and rice are portioned according to the information our clients provided when they signed up. our clients come to us to get the appropriate amount of food for their goals, so this step is very important.

For the final step in the process, we use our T-300 Multivac Machine. The Multivac Machine allows us to reduce the oxygen environment in the meals down to 1%. Removing the oxygen slows the oxidation of the ingredients allowing them to last longer. While the technology does state meals can last 12 days, we still strongly recommend consuming meals within 5-7 days of delivery.